Top 10 Electric Motor Controller Features You Need to Know

In recent years, the demand for electric motor controllers has surged, driven by the increasing adoption of electric vehicles and automation technologies across various industries. According to a report by Market Research Future, the global electric motor controller market is projected to reach USD 22 billion by 2025, growing at a CAGR of 5.2%. Electric motor controllers play a crucial role in managing the performance of electric motors, ensuring efficiency, precision, and reliability in their operation.

Experts in the field, such as Dr. Michael Schmidt, a prominent researcher in electric drive systems, have emphasized the significance of understanding the key features of electric motor controllers. He stated, "The evolution of electric motor controllers is pivotal for the advancement of modern electric systems, enabling higher performance and efficiency." As industries continue to explore innovative solutions to enhance energy usage and reduce emissions, comprehending the features of electric motor controllers is essential for engineers and designers aiming to optimize their applications.

In this article, we will delve into the top 10 features of electric motor controllers that are crucial for achieving optimal performance and meeting the demands of an evolving marketplace. Understanding these features not only aids in the selection of appropriate controllers but also enhances the overall efficacy of electric motor systems in real-world applications.

Key Functions of Electric Motor Controllers Explained

Electric motor controllers are critical components in various applications, ranging from electric vehicles to industrial machinery. They primarily serve to regulate the speed and torque of electric motors by controlling the power supplied to them. One key function of electric motor controllers is their ability to manage the acceleration and deceleration of a motor, allowing for smooth transitions during operation. This feature enhances user experience and improves the longevity of the motor by preventing sudden jerks that could cause mechanical strain.

Another important aspect is the ability to monitor and protect against faults. Advanced motor controllers come equipped with built-in diagnostics that can detect issues such as overcurrent, overheating, or voltage irregularities. By continually assessing the health of the motor system, these controllers can initiate safety measures, such as shutting down the motor to prevent damage. Additionally, many modern controllers support various communication protocols, enabling users to integrate them into smart systems for real-time monitoring and control. This level of functionality not only increases efficiency but also enhances the overall performance of electric motor systems across different industries.

Top 10 Electric Motor Controller Features You Need to Know

| Feature | Description | Importance |

|---|---|---|

| PID Control | Proportional-Integral-Derivative control for maintaining desired speed or position. | High |

| Regenerative Braking | Recovers energy during braking to improve efficiency. | Moderate |

| Thermal Management | Keeps the controller within optimal temperature ranges. | High |

| Current Limiting | Prevents motor and controller damage by limiting current. | High |

| Communication Protocols | Supports various protocols like CAN, UART for enhanced integration. | Moderate |

| Fault Monitoring | Detects and reports faults to prevent damage and ensure reliability. | High |

| Overvoltage Protection | Protects against voltage spikes that could damage the system. | High |

| Speed Control | Allows precise control of motor speed for various applications. | High |

| User Interface | Displays real-time data and allows user adjustments. | Moderate |

| Software Configuration | Enables fine-tuning of controller parameters via software. | High |

Types of Electric Motor Controllers and Their Applications

Electric motor controllers are vital components in various applications, managing the power delivery and performance of electric motors. Understanding the different types of electric motor controllers can help you choose the right one for your needs. The main types include DC motor controllers, which are commonly used in applications requiring precise speed control, such as robotics and electric vehicles. On the other hand, AC motor controllers are prevalent in larger industrial applications, facilitating the operation of induction and synchronous motors in systems like conveyor belts and pumps.

When selecting an electric motor controller, consider the specific application requirements. For instance, regenerative braking functionality can enhance efficiency in electric vehicle systems by recovering energy during deceleration. Additionally, look for controllers that offer compatibility with various communication protocols to ensure seamless integration with your existing systems.

Tips: Always check the power ratings and current handling capabilities of the motor controller to match them with your motor's specifications. It’s also beneficial to evaluate the controller’s thermal management features, as efficient heat dissipation can prolong the lifespan of both the controller and the motor. Lastly, ensure the controller has adequate protection features such as over-voltage and over-temperature safeguards to prevent potential damage in unforeseen circumstances.

Essential Features for Performance Optimization in Controllers

When selecting an electric motor controller, understanding essential features for performance optimization is critical to ensuring maximum efficiency and longevity of your electric drive system. One of the foremost attributes to consider is the controller's power range, which dictates how well the controller can handle varying loads. A controller with a broad power range allows for adaptability in different operating conditions, ensuring that the motor performs optimally under diverse circumstances, such as acceleration, cruising, or deceleration.

Another critical feature is the controller's responsiveness. A high-quality electric motor controller should provide real-time feedback and adjustments, enabling smooth operation and enhanced performance. This is often achieved through advanced algorithms that modulate the power delivery based on the motor's demand, reducing energy wastage and improving torque delivery. Additionally, the integrated thermal management systems within controllers play a pivotal role in maintaining optimal operating temperatures, which can significantly enhance reliability and prevent overheating issues, prolonging the lifespan of both the controller and the motor.

In summary, focusing on these features can dramatically improve the overall performance and efficiency of electric motor systems.

Safety Features in Electric Motor Controllers: What to Look For

When evaluating electric motor controllers, safety features are paramount. A report by the International Electrotechnical Commission (IEC) indicates that nearly 50% of motor failures can be attributed to inadequate protective measures. Key features to consider include overcurrent protection, which safeguards the motor from excessive current that could lead to overheating and permanent damage. Additionally, thermal protection is crucial; many controllers now incorporate temperature sensors that automatically shut down the motor if temperatures exceed safe operating limits, reinforcing the system's safety.

Another important aspect is fault detection capabilities. According to a study published in the IEEE Transactions on Industrial Electronics, systems equipped with advanced fault diagnostics can reduce maintenance costs by up to 30%. Such systems monitor the controller’s performance in real-time, allowing for immediate identification of issues like short circuits or malfunctioning components. Moreover, features like safe torque off (STO) ensure that the motor can be quickly disengaged in case of an emergency, adding an essential layer of protection for operators and equipment alike. As electric motor technology continues to evolve, prioritizing these safety features in controller selection will be vital for effective and secure operation.

Future Trends in Electric Motor Controller Technology and Innovations

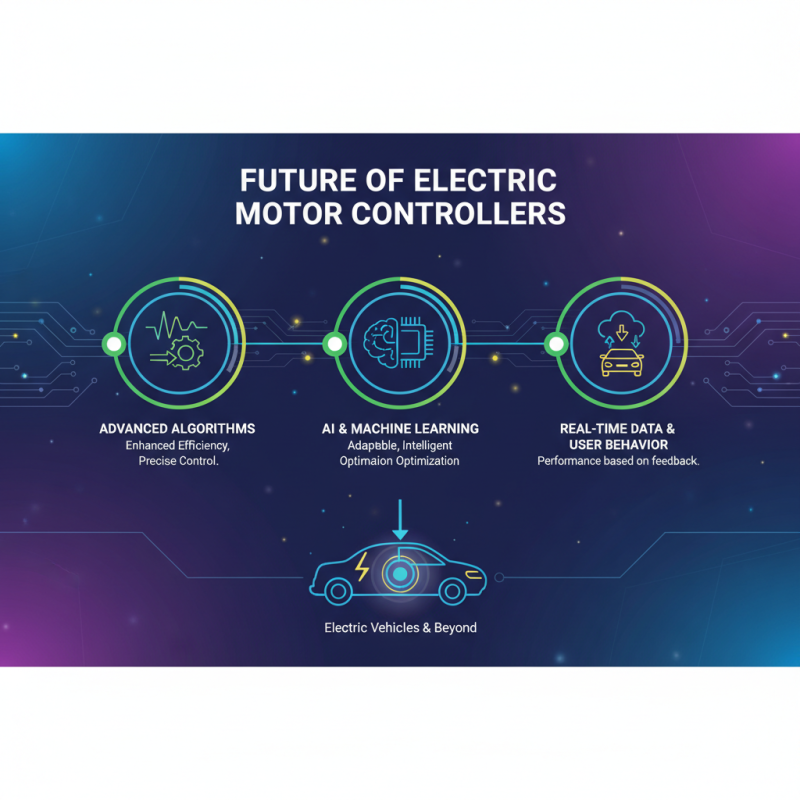

As electric motor controller technology continues to evolve, several key trends are emerging that will shape the future of this essential component in electric vehicles and other applications. One notable trend is the shift towards more advanced algorithms for control strategies. These algorithms enhance the efficiency of electric motor systems, enabling precise control over speed and torque while minimizing energy loss. As machine learning and artificial intelligence mature, we can expect controllers to be more adaptable and intelligent, optimizing performance based on real-time data and user behavior.

Another significant innovation on the horizon is the integration of smart connectivity features into electric motor controllers. With the rise of the Internet of Things (IoT), future controllers will likely allow for seamless communication between devices, enabling remote monitoring and diagnostics. This connectivity not only boosts operational efficiency but also enhances the user experience by providing valuable insights and predictive maintenance alerts.

Tips: When considering the future of electric motor controllers, prioritize features such as compatibility with IoT systems and adaptive algorithms for improved efficiency. Stay informed about emerging technologies that may influence controller design, and be ready to explore options that offer scalable solutions as your needs evolve. Investing in smart controllers now can pave the way for a more sustainable and responsive electric motor system in the future.

Related Posts

-

Best 10 Circuit Control Techniques You Need to Know for Your Projects

-

2025 How to Successfully Install Electrical Wiring Using Industry Best Practices

-

How to Choose the Right Soft Starters for Your Industrial Applications

-

Top 10 Tips for Choosing the Best Power Controller for Your Needs

-

2025 How to Choose the Right Disconnect Switch for Your Electrical Needs

-

2025 Top Trends in Motor Control Centers and Their Impact on Industry Efficiency

Skip to content

Skip to content