What is an Electric Motor Controller and How Does It Work?

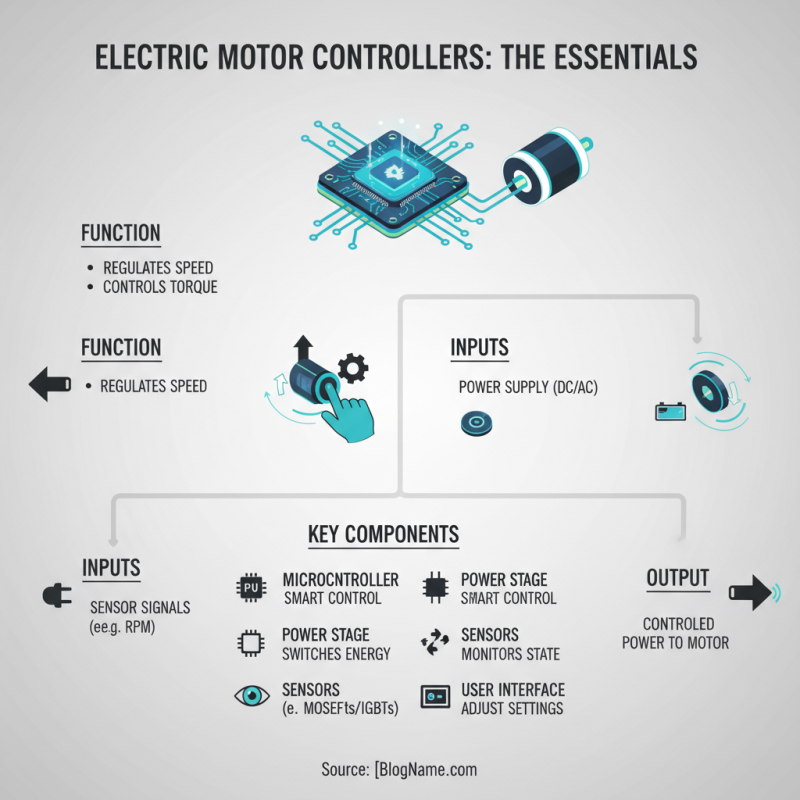

An electric motor controller is a pivotal component in modern electrical systems. It regulates the power supply to electric motors. Understanding its function is essential for various applications, from electric vehicles to industrial machines.

The electric motor controller manages speed, torque, and direction. It transforms electrical signals into precise control, ensuring efficiency. Without this device, motors would lack performance and reliability. Detailed knowledge of how it operates can reveal its significance in daily technology.

However, mastering electric motor controllers is not straightforward. There are different types, including DC and AC controllers. Each has unique characteristics and applications. This complexity can lead to confusion, especially for beginners. Yet, exploring its mechanisms can enhance understanding and lead to innovative uses.

Definition of an Electric Motor Controller and Its Importance

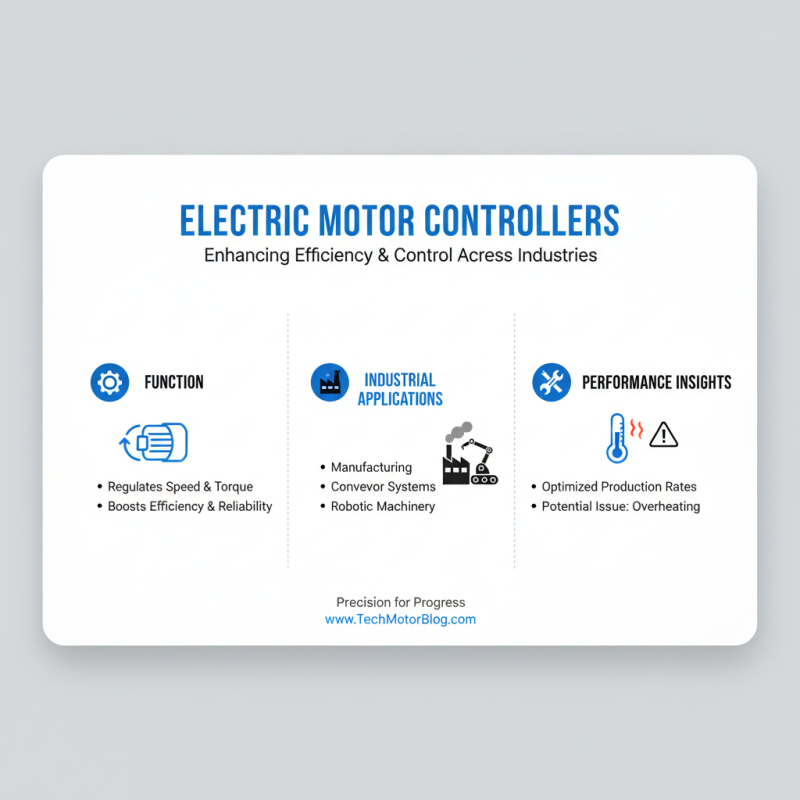

An electric motor controller is essential in managing the performance of electric motors. It regulates the speed, torque, and direction of motor operation. This device enhances efficiency and allows for precise control of electric motors in various applications, from industrial machinery to electric vehicles. According to a recent industry report, demand for electric motor controllers is projected to grow by 15% annually through 2028. This growth reflects their critical role in the shift toward automation and sustainability.

The importance of electric motor controllers becomes clear in energy management. They help optimize power consumption, which is crucial for reducing operational costs. For instance, smart controllers can adjust motor output based on load conditions, leading to energy savings of up to 30%. This capability not only lowers expenses but also contributes to a more sustainable operating environment. However, transitioning to advanced motor control systems can pose challenges. Companies must invest in training and infrastructure to fully leverage these technologies.

Tips: Regularly monitor your motor controller settings. Proper calibration can lead to significant energy savings. Understand your operational needs and adjust the controller for maximum efficiency. Don’t hesitate to evaluate your existing systems. Continuous improvement can lead to better performance and lower costs.

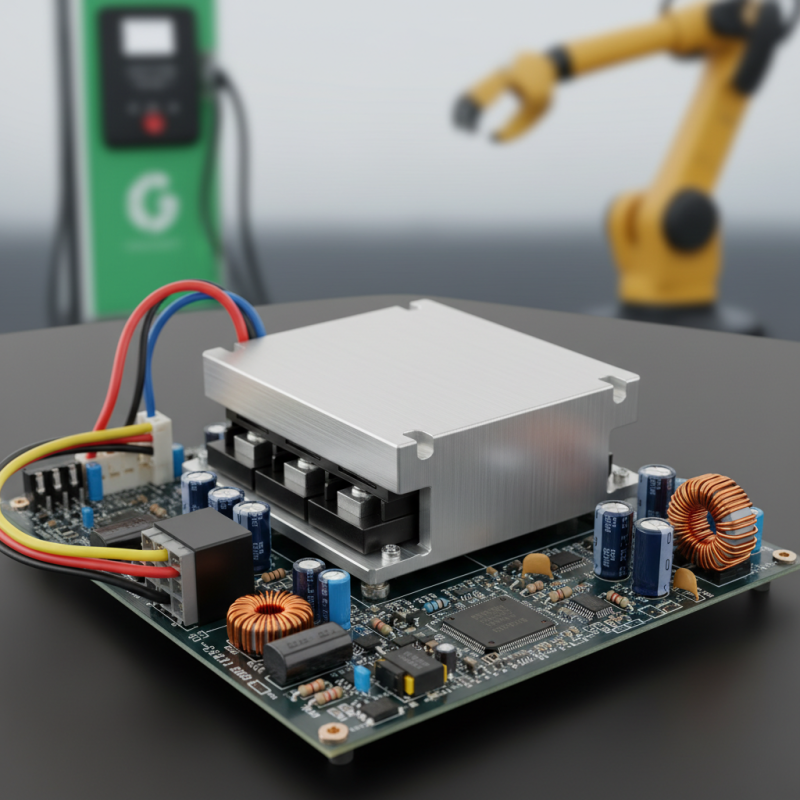

Key Components of Electric Motor Controllers and Their Functions

Electric motor controllers are essential for managing electric motors. They regulate the speed and torque of the motor by controlling the electrical energy supplied to it. Let’s explore the key components of electric motor controllers and their functions.

At the heart of a motor controller is the power circuit. This circuit adjusts the voltage and current flowing to the motor. It includes essential parts such as transistors or MOSFETs. These components switch the current on and off rapidly. This process allows for precise motor control.

Another crucial component is the control circuit. This circuit interprets signals, such as those from sensors. It processes inputs and adjusts the power circuit accordingly. An effective control circuit enables the motor to respond swiftly to changes.

**Tip:** Regular maintenance of motor controllers can help enhance performance.

Lastly, feedback devices, such as encoders or potentiometers, provide real-time data. These devices help the controller understand the motor's position or speed. Without feedback, the system may operate inefficiently. This may cause overheating or energy loss.

**Tip:** Choosing the right feedback device for your system is critical.

Understanding these components can enhance efficiency. However, the complexity of these systems often leaves room for improvement. Keep reflecting on your needs and the performance of your controller.

Types of Electric Motor Controllers: Analogue vs. Digital

Electric motor controllers are essential for managing the performance of electric motors. Two primary types of controllers exist: analogue and digital. Analogue controllers are simpler. They use basic circuitry to regulate motor functions. These systems can be cost-effective. However, they often lack precision. For some applications, this can mean less efficiency.

Digital controllers are gaining popularity due to their advanced capabilities. They can process data more quickly, providing better performance. In fact, a report from the International Energy Agency highlights that digital motor controllers can improve energy efficiency by up to 30%. This is particularly beneficial in industrial settings. Digital systems allow for more refined control of speed and torque.

However, there are trade-offs. Digital controllers may require more complex programming and maintenance. This can lead to higher installation costs for businesses. Some industries are still hesitant to adopt digital solutions. Recent surveys show that nearly 40% of companies prefer traditional analogue systems. Despite the advantages of digital controllers, the transition isn’t always straightforward.

How Electric Motor Controllers Regulate Motor Speed and Torque

Electric motor controllers play a crucial role in regulating motor speed and torque, ensuring efficient operation of electric motors across various applications. These controllers can vary in complexity, but their fundamental function remains the same: they manipulate the electrical input to the motor. According to recent industry reports, approximately 60% of industrial motors use variable frequency drives (VFDs) to manage speed and torque effectively.

This technology allows for precise adjustments to the motor's operating conditions. By changing the frequency and voltage supplied to the motor, the controller can fine-tune its performance. For instance, a VFD can reduce motor speed to conserve energy when full power is unnecessary. Studies indicate that implementing such controllers can lead to energy savings of up to 30%, which is significant in industrial settings where motors are often running continuously.

However, challenges remain. Not all motors are compatible with advanced controllers, leading to inefficiencies. Additionally, improper settings can cause overheating or reduced lifespan of the motor. Technicians must ensure correct installation and configuration to avoid these pitfalls. Continuous training and knowledge sharing in the sector can help mitigate these issues, improving overall motor performance and lifespan.

Applications of Electric Motor Controllers in Various Industries

Electric motor controllers are essential in various industries. They regulate the speed and torque of electric motors. This regulation enhances efficiency and control. In manufacturing, these controllers drive conveyor systems and robotic machinery. Precise motor control boosts production rates and reliability. However, not all systems work perfectly. Issues like overheating can arise, affecting performance.

In the automotive sector, electric motor controllers are vital for electric vehicles. They manage power delivery to the motors, ensuring smooth acceleration. Additionally, they help in regenerative braking, recovering energy. Yet, the technology faces challenges. Some designs may struggle in extreme temperature conditions, impacting functionality.

In renewable energy, electric motor controllers play a role in wind turbines and solar trackers. They optimize motor performance to align with changing wind speeds and sunlight. This optimization is crucial for maximum energy capture. At times, these systems need recalibration to address inefficiencies. Continuous development is necessary to overcome these hurdles and improve system resilience.

Related Posts

-

2025 Top Trends in Motor Control Centers and Their Impact on Industry Efficiency

-

What is a Motor Control Circuit and How Does it Work in 2026

-

Why is Motor Disconnect Important for Safe Electrical Operations

-

Top 5 Circuit Power Solutions Driving Efficiency in Modern Electronics

-

Why Are Disconnect Switches Essential for Electrical Safety and Efficiency

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

Skip to content

Skip to content