2025 Top Trends in Motor Control Centers and Their Impact on Industry Efficiency

The industrial landscape is undergoing a significant transformation, driven by advancements in technology and changing market demands. As companies strive to improve efficiency and operational effectiveness, motor control centers (MCCs) are taking center stage as essential components in modern manufacturing and processing environments. These centralized systems not only streamline the control of electrical motors but also integrate advanced features that enhance monitoring, diagnostics, and overall system performance.

In 2025, we anticipate a convergence of innovative trends within motor control centers that will redefine their role in industrial applications. From the adoption of smart technologies such as IoT connectivity to the implementation of energy-efficient designs, these trends promise to enhance productivity while reducing operational costs. Furthermore, the integration of sustainable practices within MCCs will play a crucial role in minimizing environmental impact, aligning with the growing emphasis on eco-friendly practices in industry.

As we explore these top trends in motor control centers, it is essential to consider their far-reaching implications for industry efficiency. Understanding how these advancements can lead to improved performance, reliability, and responsiveness will be key for organizations looking to thrive in an increasingly competitive market.

Top Trends in Motor Control Centers for 2025

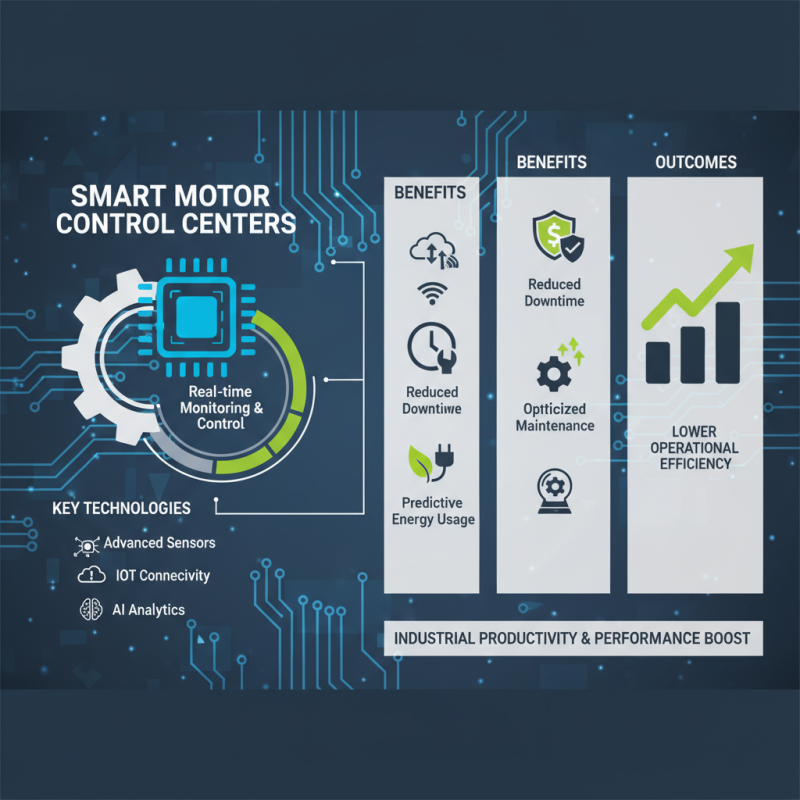

As we approach 2025, the landscape of motor control centers (MCCs) is evolving rapidly, driven by advancements in technology and a growing emphasis on industrial efficiency. One of the most significant trends is the integration of smart technologies within MCCs. This includes the implementation of IoT devices that allow for real-time monitoring and data analytics. With this technology, operators can gain insights into machinery performance and energy consumption, enabling predictive maintenance and reducing unexpected downtimes, ultimately leading to significant cost savings.

Another trend reshaping motor control centers is the move towards modular design. Modular MCCs offer flexibility in configuration, allowing industries to adapt and scale their operations with ease. This adaptability not only enhances operational efficiency but also facilitates quicker responses to changing market demands. Additionally, improved safety features are being integrated into these systems to protect both personnel and equipment, fostering a more secure working environment. Overall, these trends indicate a transformative change in MCCs, positioning them as critical components in the pursuit of enhanced productivity and sustainability in various industrial sectors.

2025 Top Trends in Motor Control Centers and Their Impact on Industry Efficiency

| Trend | Description | Impact on Efficiency | Expected Adoption Rate (%) |

|---|---|---|---|

| Smart Motor Control Centers | Integration of IoT and AI technologies for real-time monitoring and predictive maintenance. | Improved uptime and reduced maintenance costs. | 70% |

| Energy Efficiency Solutions | Implementation of systems that optimize power usage in motor operations. | Lower energy costs and reduced carbon footprint. | 80% |

| Modular Designs | Use of standard components to create flexible control centers that can be easily updated or expanded. | Easier upgrades and maintenance, increased operational flexibility. | 65% |

| Remote Monitoring and Control | Capabilities for operators to monitor and control systems remotely via secure networks. | Faster response times to issues and lower operational costs. | 75% |

| Enhanced Safety Features | Advanced safety protocols and features to mitigate risks in motor operations. | Reduced incidents and compliance with safety regulations. | 85% |

Impact of Smart Technology on Motor Control Efficiency

The integration of smart technology in motor control centers (MCCs) is reshaping industrial efficiency and productivity. By leveraging advanced sensors, IoT connectivity, and AI-driven analytics, modern MCCs are capable of real-time monitoring and control, resulting in enhanced operational performance. This transformative approach allows industries to reduce downtime, optimize energy usage, and predict maintenance needs, which directly contributes to lower operational costs and increased overall efficiency.

To maximize the benefits of smart technology in motor control, consider implementing predictive maintenance strategies. Using data analytics, you can forecast potential equipment failures before they occur, ensuring timely interventions and minimizing unplanned outages. Additionally, investing in energy management systems can provide valuable insights into your energy consumption patterns, enabling you to make informed decisions that optimize resource allocation.

Lastly, prioritize training for your team on the latest technologies and tools associated with smart MCCs. A well-informed workforce is crucial in harnessing the full potential of these advancements. As motor control centers evolve, embracing education will empower your employees to effectively utilize new systems, driving your organization toward greater innovation and efficiency.

Energy Savings and Sustainability in Motor Control Centers

As industries increasingly focus on energy efficiency and sustainability, the evolution of Motor Control Centers (MCCs) plays a vital role in meeting these goals. By incorporating advanced technologies such as variable frequency drives (VFDs) and smart sensors, MCCs significantly enhance the management and monitoring of electrical motors. This not only minimizes energy consumption but also optimizes operational performance. The integration of intelligent control systems within MCCs allows for real-time data analytics, enabling industries to identify inefficiencies and implement corrective measures swiftly.

Moreover, the drive toward sustainable practices compels manufacturers to consider the life cycle of their motor control solutions. By utilizing energy-efficient components and eco-friendly materials in the construction of MCCs, industries can reduce their carbon footprint. The implementation of predictive maintenance strategies within MCCs helps extend equipment life, thus minimizing waste and resource consumption. As companies adopt these innovative approaches, they not only improve their bottom line but also contribute positively to environmental stewardship, creating a win-win scenario for both industry and planet.

Integration of IoT in Motor Control Systems: Benefits and Challenges

The integration of the Internet of Things (IoT) into motor control systems is reshaping the landscape of industrial automation. By facilitating real-time data exchange between machines and operators, IoT-enabled motor control centers enhance operational visibility and efficiency. These systems allow for the remote monitoring of equipment performance, enabling timely interventions that can prevent costly downtime. With predictive analytics powered by IoT data, industries can anticipate maintenance needs, thereby extending equipment life and optimizing resource allocation.

However, the implementation of IoT in motor control systems comes with notable challenges. One prominent concern is cybersecurity; as these systems become more interconnected, they may be vulnerable to cyber threats that could disrupt operations. Additionally, integrating legacy systems with modern IoT technologies requires careful planning and execution, often demanding significant investments in infrastructure upgrades. Companies must navigate these hurdles while ensuring compliance with industry standards and maintaining system reliability to truly benefit from the IoT revolution in motor control.

2025 Trends in Motor Control Centers: Impact of IoT Integration

Future Workforce Skills Required for Advanced Motor Control Technologies

As the industry shifts towards increasingly sophisticated motor control technologies, the future workforce will need to adapt by acquiring a new set of skills tailored to these advancements. According to a report by the International Society of Automation, nearly 70% of employers in the manufacturing sector anticipate a gap in skilled labor as automation and smart technologies become prevalent. This gap highlights the urgent need for workers proficient in areas such as artificial intelligence, data analytics, and cyber-physical systems, which are becoming integral components of motor control centers.

Furthermore, a study by the National Institute of Standards and Technology emphasizes that proficiency in digital technologies is essential for the future workforce. With advanced motor control systems often incorporating IoT devices and machine learning algorithms, operators must be well-versed in not only traditional mechanical and electrical skills but also in programming and systems integration. Training programs must evolve to include modules on software development, cybersecurity measures, and maintenance of intelligent systems, ensuring that employees are prepared for the complexities of modern industrial environments. This holistic approach to skill development will be critical in addressing the challenges posed by the rollout of advanced motor control technologies, ultimately enhancing overall industrial efficiency.

Related Posts

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

-

Essential Tips for Improving Motor Control in Daily Activities

-

How to Choose the Best Motor Control Solutions for Your Needs

-

Best 10 Circuit Control Techniques You Need to Know for Your Projects

-

2025 How to Choose the Right Disconnect Switch for Your Electrical Needs

-

Top 5 Circuit Power Solutions Driving Efficiency in Modern Electronics

Skip to content

Skip to content