Top 10 Tips for Choosing the Best Power Controller for Your Needs

Choosing the right power controller can significantly impact the efficiency and reliability of your electrical systems. A power controller regulates the supply of power to various components, ensuring that they operate within their designated parameters. With a multitude of options available on the market, finding the ideal power controller tailored to your specific needs can be a daunting task. Whether you are upgrading existing systems or embarking on a new project, understanding the essential features and functionalities of power controllers is crucial for making an informed decision.

This article provides you with the top 10 tips to guide your selection process. From assessing the power requirements of your application to considering compatibility and control options, these insights will help you navigate the complexities of power controller options. By carefully evaluating each factor, you will not only optimize performance but also enhance the longevity of your systems. Let's explore these valuable tips to ensure you choose the best power controller for your unique needs.

Understanding the Basics of Power Controllers and Their Functionality

When selecting a power controller, understanding the basics of their functionality is crucial to ensure optimal performance for your specific needs. Power controllers are devices that regulate the voltage and current supplied to electrical equipment, enhancing energy efficiency and minimizing power wastage. According to a report by the International Energy Agency, the implementation of advanced power management systems can reduce energy consumption by up to 20% in industrial applications. This highlights the significance of choosing the right power controller to improve operational efficiency and reduce costs.

Different types of power controllers vary in terms of their operating mechanisms and features. For instance, thyristor-based controllers are ideal for high-power applications, while PWM (Pulse Width Modulation) controllers are more suited for applications requiring precise control over power delivery. A comprehensive market analysis from MarketsandMarkets indicates that the global power controller market is projected to grow significantly, driven by an increasing demand for energy-efficient devices. Understanding these distinctions can help make informed decisions that tailor solutions to both current and future demands, ultimately ensuring seamless operation in various applications.

Top 10 Tips for Choosing the Best Power Controller for Your Needs

Identifying Your Specific Power Requirements and Load Types

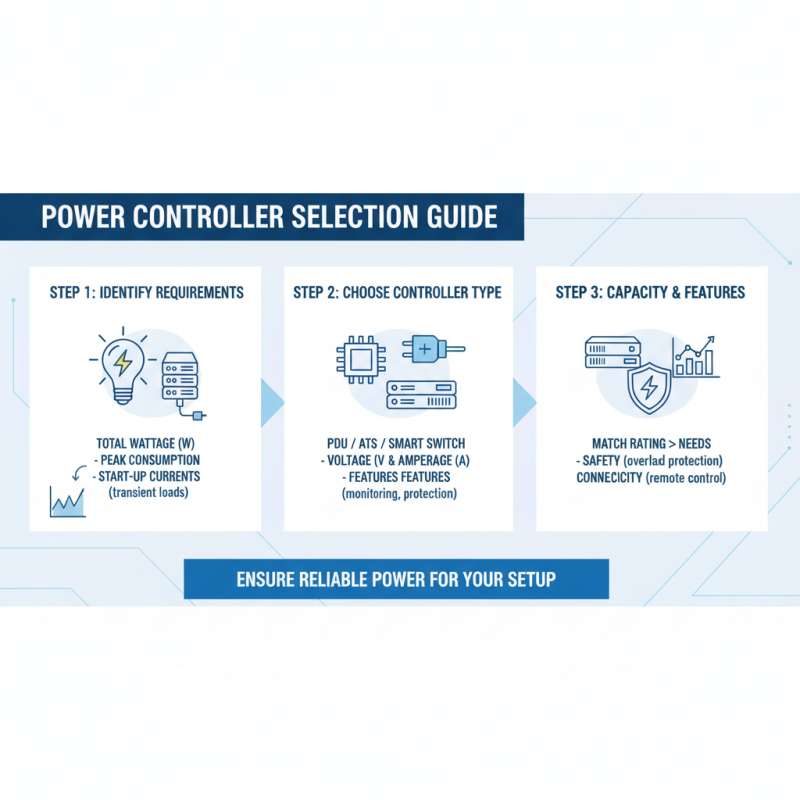

When selecting a power controller, the first step is to accurately identify your specific power requirements. This involves assessing the total wattage of all devices that will be connected to the controller. It's crucial to consider not just the peak power consumption but also the start-up currents of devices, which can be significantly higher than their normal operational loads. This understanding helps in choosing a controller that can handle both the continuous and transient demands of your application.

Additionally, recognizing the types of loads you will be working with is essential. Loads can be categorized into resistive, inductive, and capacitive types, each presenting unique characteristics and challenges. For instance, inductive loads like motors require controllers that can manage inrush current effectively, while resistive loads, such as heating elements, have more straightforward power requirements. By carefully analyzing the nature of your loads and their respective power factors, you can select a controller that is optimized for both efficiency and reliability, ensuring a seamless operation tailored to your specific needs.

Evaluating the Compatibility of Power Controllers with Your Equipment

When selecting a power controller, one of the most critical steps is evaluating its compatibility with your existing equipment. Not all power controllers are created equal; they vary in features, voltage ranges, and output capabilities. To ensure seamless integration, you must first assess the specifications of your current system, including voltage requirements and load types. By matching these parameters with the power controller's technical data, you can avoid potential issues that might arise from incompatible equipment.

Furthermore, consider the communication protocols that your devices use. Some power controllers may offer advanced features such as remote monitoring or control, but these capabilities are only useful if they align with the technology used by your equipment. It's essential to check if the power controller supports the protocols necessary for your setup. Additionally, understanding the physical space requirements and connector types will help streamline the installation process. By focusing on these compatibility aspects, you can select a power controller that not only meets your operational needs but also enhances the overall efficiency and longevity of your equipment.

Considering Control Features and User Interface for Ease of Use

When choosing the best power controller for your needs, the control features and user interface play a critical role in ensuring ease of use and operational efficiency. Users should first assess the specific functionalities offered by the controller. Look for features such as PWM (Pulse Width Modulation) control, programmable settings, and feedback systems that can help in fine-tuning the power output according to your requirements. A controller that provides diverse control options facilitates a tailored approach, ensuring that it meets various operational demands.

Additionally, the user interface is crucial for a seamless user experience. An intuitive layout can significantly reduce the learning curve, making it easier to navigate through settings and adjustments. Controllers equipped with digital displays, touchscreens, or mobile compatibility allow for real-time monitoring and adjustments, enhancing overall flexibility. Ensure that the interface not only offers clear visibility of key parameters but also provides easy access to necessary functions. A well-designed user interface can make troubleshooting simpler and enhance overall user satisfaction, making the power controller more efficient and enjoyable to use.

Assessing Manufacturer Reputation and Warranty Options for Reliability

When selecting a power controller, assessing the manufacturer's reputation and warranty options is paramount for ensuring long-term reliability. According to a recent industry report, nearly 70% of users agree that a strong warranty significantly factors into their purchasing decision. A reputable manufacturer typically stands behind their product with robust warranty offerings, providing consumers with peace of mind. Look for manufacturers with a history of positive customer feedback and industry certifications, as this often correlates with fewer product failures and enhanced performance.

It’s also wise to consider the warranty terms carefully. Not only does a good warranty protect your investment, but it often reveals the manufacturer's confidence in their product quality. Reports indicate that products with a warranty of five years or more tend to have lower failure rates, highlighting the importance of choosing a power controller backed by a solid warranty.

In summary, prioritize manufacturers with a good market standing and comprehensive warranty options. Explore user reviews, seek out independent evaluations, and don't hesitate to reach out to current users for their experiences. Ultimately, investing time in researching these aspects before making a purchase will lead to better outcomes and overall satisfaction with your power controller choice.

Top 10 Tips for Choosing the Best Power Controller for Your Needs

| Tip | Description | Importance | Manufacturer Reputation | Warranty Options |

|---|---|---|---|---|

| 1 | Evaluate the load requirements | High | Check reviews and ratings | Minimum 1 year |

| 2 | Consider control features | Medium | Established brands preferred | Up to 3 years |

| 3 | Review compatibility with equipment | High | Reputation in the industry | 5 years preferred |

| 4 | Check for safety certifications | High | Positive customer feedback | Limited lifetime warranty |

| 5 | Assess energy efficiency | Medium | Multiple industry awards | 2 years as standard |

| 6 | Seek user-friendly interfaces | Medium | Strong technical support | 3 years |

| 7 | Check installation requirements | Medium | Long history in the market | 1 year for parts |

| 8 | Compare pricing and value | High | Known for reliability | 2 years, optional extensions |

| 9 | Understanding customer service options | High | Transparent practices | 1 year with guaranteed response |

| 10 | Gather user testimonials | Medium | Recognized by industry experts | Repair guarantee available |

Related Posts

-

Best 10 Circuit Control Techniques You Need to Know for Your Projects

-

2025 How to Successfully Install Electrical Wiring Using Industry Best Practices

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

-

Why Are Disconnect Switches Essential for Electrical Safety and Efficiency

-

Top 5 Circuit Power Solutions Driving Efficiency in Modern Electronics

-

How to Choose the Best Integrated Circuit Solutions for Your Projects

Skip to content

Skip to content