How to Choose the Right Soft Starters for Your Industrial Applications

In the realm of industrial applications, the selection of appropriate soft starters is pivotal for ensuring efficient operation and longevity of equipment. As leading industry expert Dr. John Stevens notes, "Choosing the right soft starter can significantly enhance motor performance and reduce downtime," highlighting the critical nature of this decision. Soft starters serve to regulate the starting current and torque of electric motors, preventing mechanical stress and minimizing energy consumption during the startup phase.

Understanding the various types of soft starters available, along with their features and benefits, is essential for engineers and facility managers tasked with optimizing machinery performance. The right choice can lead to improved reliability and energy efficiency, fostering a more sustainable industrial environment. With the complexity of modern industrial systems and the diverse range of soft starters on the market, careful consideration and a thorough evaluation of specific application requirements become imperative. This discussion aims to provide insights into the essential factors to consider when selecting soft starters, paving the way for informed decision-making in industrial settings.

Understanding Soft Starters: Definitions and Applications in Industry

Soft starters are essential devices in industrial applications, enabling the smooth initiation of electric motors. By gradually increasing voltage and current, they reduce the inrush current, which can lead to mechanical and electrical stress. In particular, industries such as manufacturing, HVAC, and water treatment utilize soft starters to ensure reliable performance and prolonged equipment life. According to a recent report by Global Industry Analysts, the market for soft starters is projected to grow significantly, reaching an estimated USD 1.5 billion by 2026, indicating the increasing reliance on these devices in various industrial sectors.

Understanding the specific applications of soft starters within the industry is crucial. For example, in pump and fan systems, soft starters help prevent water hammer and excessive torque, contributing to operational efficiency and minimizing maintenance costs. The International Electrotechnical Commission (IEC) highlights that in heavy machinery operations—like crushers and conveyors—soft starters can enhance safety protocols by managing the startup sequence effectively. This capability not only protects the equipment but also ensures that operators can maintain optimal performance under varied load conditions, making soft starters a vital component in modern industrial operations.

Key Factors to Consider When Selecting Soft Starters for Equipment

When selecting the right soft starter for your industrial applications, several key factors must be evaluated to ensure optimal performance and compatibility with your equipment. First, consider the voltage and current ratings of the soft starter. Make sure they align with the specifications of the motor and the overall electrical system. Additionally, pay attention to the phase type—whether your application requires single-phase or three-phase soft starters—as this will significantly influence the efficiency of your startup operations.

Another critical factor is the control method of the soft starter. Some models offer advanced features such as soft-stop capabilities, which can extend the lifespan of both the motor and the connected equipment by reducing mechanical stress during startup and shutdown. It’s also essential to assess the environmental conditions where the soft starter will be installed, including factors like temperature, humidity, and dust exposure, to select a unit that can withstand such elements.

**Tips:** Always consider the installation and operational ease of the soft starter. A model with user-friendly interfaces and clear diagnostic features will save time and hassle during setup and maintenance. Regularly review the operational data collected from the soft starter to enhance performance and detect potential issues early on. Ensure that the soft starter you choose has adequate support for troubleshooting and technical assistance when needed.

Key Factors to Consider When Selecting Soft Starters for Equipment

This bar chart illustrates the key factors to consider when selecting soft starters for industrial applications. Each factor is rated on a scale from 1 to 10, indicating its importance. Factors include current rating, voltage rating, starting torque, control features, cost, and size.

Comparative Analysis of Soft Starter Types and Their Performance Metrics

When selecting the appropriate soft starter for industrial applications, understanding the different types and their performance metrics is essential. Soft starters primarily fall into three categories: current limiting, voltage ramping, and reactive soft starters. Current limiting soft starters are designed to reduce the inrush current significantly, which can be critical for applications involving large motors. Studies have shown that these starters can decrease starting current by up to 70%, maintaining the integrity of power distribution during startup.

In contrast, voltage ramping soft starters provide a controlled increase in voltage, offering a gradual acceleration of the motor. This type can enhance motor performance by reducing mechanical stress, with some reports indicating a potential decrease in wear-related failures by over 30%. Reactive soft starters, on the other hand, are optimized for specific load types and applications, often resulting in higher overall efficiency compared to their counterparts. Industry analyses reveal that selecting a suitable soft starter can improve energy efficiency metrics by nearly 15% while also extending equipment life cycles significantly.

Ultimately, the choice between these soft starter types should be guided by a detailed examination of performance metrics such as starting torque, thermal management, and operational load characteristics. Adequate selection based on these parameters not only ensures optimal performance but also reduces operational costs in the long run.

Industry Standards and Regulations Impacting Soft Starter Selection

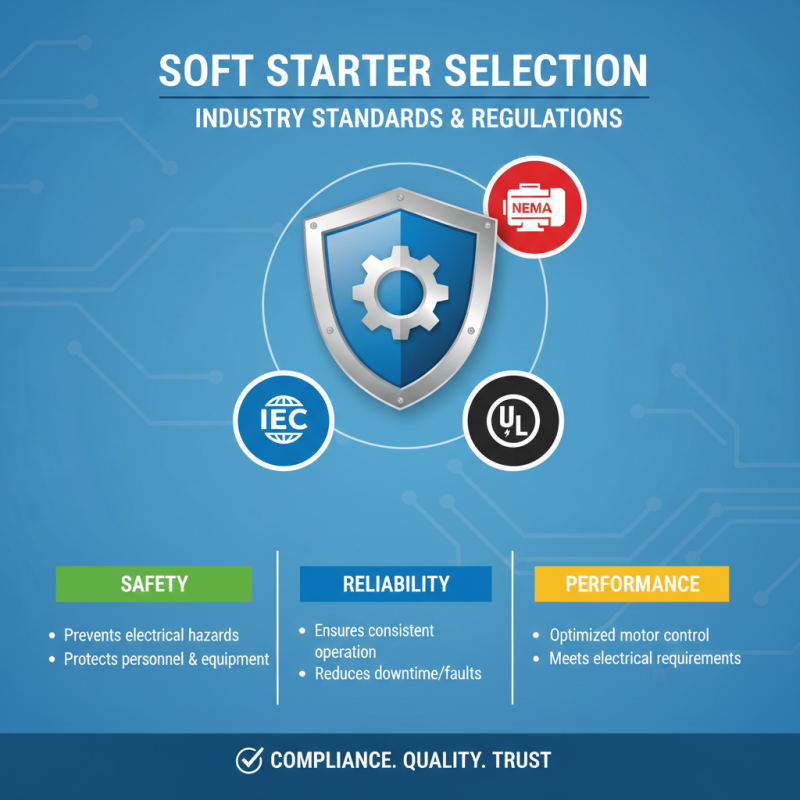

When selecting soft starters for industrial applications, industry standards and regulations play a critical role in ensuring safety, reliability, and performance. Various standards, such as IEC, NEMA, and UL, provide guidelines on the design and testing of soft starters, which help define permissible operating conditions and electrical requirements. Adhering to these standards not only ensures compliance with legal prerequisites but also fosters a culture of safety within the workplace.

Additionally, regulatory aspects related to energy efficiency and environmental impact are increasingly influencing the selection process. Many industries are now subject to stringent energy regulations aimed at reducing operational costs and carbon footprints. Soft starters that meet these regulations facilitate smoother startups while minimizing energy consumption, thereby aligning with sustainability initiatives. By considering these industry standards and regulations during the procurement process, companies can optimize their systems for better performance while ensuring that they meet necessary compliance requirements.

Case Studies: Successful Implementations of Soft Starters in Various Sectors

Soft starters have become an essential component in industrial applications, particularly due to their ability to reduce electrical stress on motors and prolong equipment lifespan. Several case studies highlight the successful implementation of soft starters across various sectors. For instance, in the manufacturing industry, a textile company reported a 30% decrease in motor failure rates after incorporating soft starters into their operations. This resulted not only in cost savings from reduced maintenance but also in increased production efficiency, enabling the company to meet demands more effectively.

In the water treatment sector, another case study showcased a facility that used soft starters to manage the high torque associated with pump start-ups. By gradually ramping up the motor speed, the facility minimized water hammer effects, leading to a 25% reduction in energy consumption during peak hours. Industry data suggests that implementing soft starters can lead to energy savings of up to 40% when compared to traditional direct-on-line (DOL) starting methods, demonstrating their value in optimizing operational costs.

**Tips:** When choosing the right soft starter, consider the specific requirements of your application, such as voltage ratings and torque control. Additionally, assess the potential energy savings by comparing different starting methods and conducting a cost-benefit analysis. Engaging with industry professionals can also provide insights into best practices and proven solutions tailored to your operational needs.

How to Choose the Right Soft Starters for Your Industrial Applications - Case Studies: Successful Implementations of Soft Starters in Various Sectors

| Industry Sector | Application | Soft Starter Type | Benefits Achieved | Implementation Year |

|---|---|---|---|---|

| Manufacturing | Conveyor Systems | Programmable Soft Starter | Reduced inrush current, improved start-up time | 2021 |

| Water Treatment | Pumps | Digital Soft Starter | Lower maintenance costs, extended motor life | 2020 |

| Mining | Crushers | Control Soft Starter | Improved torque control, energy savings | 2019 |

| Textiles | Weaving Machines | Soft Starter with Bypass | Reduced wear and tear, higher production efficiency | 2022 |

| Food Processing | Mixers | Soft Starter with Soft Stop | Reduced product damage, smoother operation | 2023 |

Related Posts

-

Essential Tips for Improving Motor Control in Daily Activities

-

How to Choose the Best Integrated Circuit Solutions for Your Projects

-

2025 How to Choose the Right Disconnect Switch for Your Electrical Needs

-

2025 Guide to Motor Control Centers: Features, Benefits, and Selection Tips

-

Why Are Disconnect Switches Essential for Electrical Safety and Efficiency

-

2025 How to Successfully Install Electrical Wiring Using Industry Best Practices

Skip to content

Skip to content